12,5 mln of investments

Capacity 330 tonnes per day

130 workers

Equipment:

- PETCUS

- A&K Development Company

- Tecflam

- IPE Steuerungstechnik

- KAMAS Westrup

- Simotec

Stages of technological process

Receiving

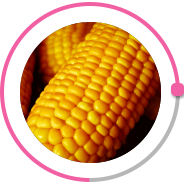

This is the first stage of seed entering the plant. Cobbles of corn brought from the field and weighed are unloaded into the pit. Then the vibroplate feeds the corn to the distribution conveyor, and from there - to the cleaning machines.

Purification and selection

The ears of corn are peeled on the 12-row husking machines “Power Husker”. Then they get to the sorting tables where the manual sanitary sorting out happens (small-sized, affected with disease or damaged ears of corn go to wastes). After weighing quality ears of corn go to the next stage – drying.

Drying

The temperature of drying ears of corn is 36-38 C° (dryer PETKUS MKT-20). The drying process lasts for about 72-120 hours depending on the hybrid structure. Constant control over humidity takes place at this stage. The quantity of taken samples depends on the humidity of corn (every 8 hours when humidity is 38%, every 4 hours with 16-20% and every hour with 16% of humidity). The drying process is finished when the humidity of the corn ears reaches 13%.

Peeling

Dried ears of corn get into the sheller (HS60/ 2SC2000 by AEC - a combined machine for shelling and preliminary cleaning of corn), the productivity of which is 30 tons per hour. Here corn seeds are separated from the corncob. At this stage, small grains and leftovers are removed. After this corn is packed into big bags and taken to the temporary storage.

Storing

Grain is stored in big bags in certified warehouses. A minimal storing term is 15 days.

Calibration

Calibration line is a set of machines by leading world producers: PETKUS, KAMAS, Westrup, Simotek, with a productivity of 140 tons per day. At this stage, the leftovers and small grains are sifted, while the quality grain is separated in four groups (large round, large flat, medium round, medium flat). The last phase of calibration is the sorting machine where the grain with inappropriate physical characteristics is removed.

Treatment

It is the process of covering the grain with the treatment substance against diseases and pests. During this process, we use batch chemical treater CT200 by PETKUS. For grain not to stick together it undergoes the phase of drying completion prevents the grain’s coalescence.

Packing

Grain is packing on automatic equipment ARODO (GRS). The daily capacity of one runs up to 4 thousand bags. We have a full control of the process (taking samples from every 5th bag) and packing.

Unloading

Packed finished grain is transporting to certified warehouses. There it is stored before dispatching by logistics department to a final consumer.

Laboratory

Laboratory includes three units: production engineering laboratory, corn laboratory and crop laboratory. LNZ Group lab corresponds to all governmental norms and standards and performs a wide range of modern grain analysis. We plan to perform infotech analysis as well. It will give us the possibility to analyze the whole grain in 1 minute, defining protein, oil, starch, gluten content, and moisture.